What is SMT manufacturing process?

1. PCB loading: PCB is usually manually put into magazine rack to facilitate automatic feeding production.

2. Colloidal (glue dispense): It seems to be used only in early circuit boards, through a "wave soldering (wave soldering)" process. Under the electronic parts, the aim is to stick the electronic parts to the circuit board after baking at the temperature, so as to prevent the electronic parts from falling into the tin furnace after wave soldering.

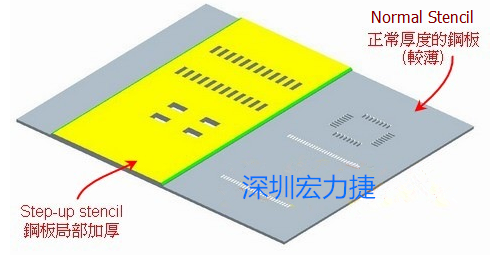

3. Tin paste / steel screen printing (solder paste printing or glue printing) (mpm): tin paste is printed on a circuit board through a steel mesh (stencil). Tin paste is a bridge between PCB and electronic parts.

4. Tin Paste Inspection: some factories do not necessarily have a tin paste inspection process, the main purpose of which is to check for defective paste printing in front of the parts patch, such as whether the offset, whether the amount of tin paste is adequate, etc. These may then be excluded or corrected prior to solder paste printing.

5. Part Patch (Pick & Place):

Fast machines-small parts (such as resistors, capacitors, inductors,) (small chip)

A slow-speed machine, a general-purpose machine, with large parts (Eg. IC, connectors).

A special-shaped machine that basically works with a clip, and can also type parts on the tray.

Hand parts-if all the machines can't be played, put them with your hands (not recommended).

6.Welding Reflow

7.AOI (Auto Optical Inspector)

Optical check whether there are wrong parts, missing parts, offset, poor eating tin, inadequate tin, solder short circuit, and the occurrence of tin ball, it is difficult to check empty welding, false welding.

8. Hand Welded Parts

Some electronic parts can not be made with existing SMT machines, if a small number of parts, will be selected [hand-welded] parts; if more will consider using [wave soldering (wave soldering)] process.

9. Board and Appearance Inspection:

The PCB is also automatically entered into the magazine rack (rack when the plate is closed, one of the purposes of which is to prevent electronic parts from bumping into each other.

How many kind of PCBA Test?

1.PCBA De-panel

V-CUT: folded plate edge

Router: similar to wash beds off the edge of the board

2.PCBA Test

MDA/ICT

PCBA Function Test

These two can be interchangeable depending on process requirements.

What is the process of box build?

1.Finished product assembly

2.Burn-In Test

3.Final Test

4.Ship to Stock