What is PCB?

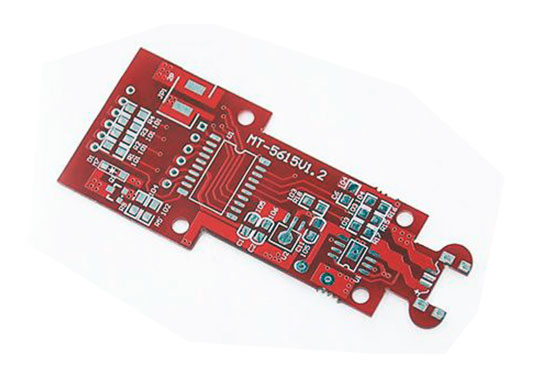

PCB (Printed Circuit Board) is the support of electronic components as well as the carrier of electrical connection of electronic components. There are a great number of types of PCBs, including single-sided, double-sided, and multilayer.

What is PCBA?

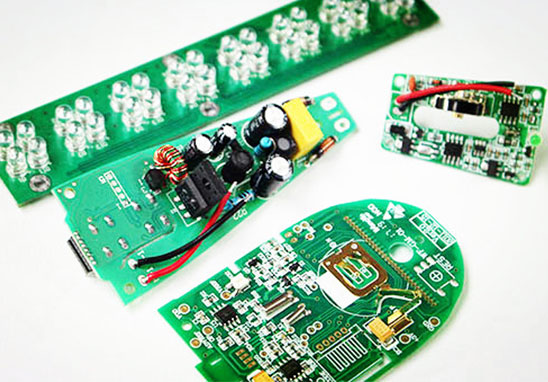

PCBA (Printed Circuit Board Assembly) is a circuit board obtained by printing solder paste on a PCB, and then mounting various components such as resistors, integrated circuits, capacitors, and transformers according to the purpose and required characteristics of the circuit board. PCBA is usually heated in a reflow oven to establish a mechanical connection between PCB and components.

The difference between PCB and PCBA

PCB is the abbreviation of printed circuit board, an important electronic component for loading electronic components, and a connection carrier for electronic component conduction. Regarding why called printed circuit board (PCB) also because using a printing technology.

PCB is divided into single layer, double-sided and multi-layer based on the circuit layer. Typical PCBs are 4-layer and 6-layer those multilayer circuit boards. More complex multilayer PCBs even have dozens of layers. Besides, PCB can also be divided into rigid board, flexible board and flexible-rigid board. Printed boards have developed from single-layer to double-sided, multilayer and flexible boards, maintaining all their respective development trends.

PCBA, Printed Circuit Board Assembly. Circuit board assembly is a term in the electronics processing industry, which mainly refers to the welding of various electronic parts, ICs and other materials or inserting them on the bare circuit board and performing quality inspection and testing to ensure that they have complete circuit connection performance.

The bare board is made according to the customer's PCB file. Therefore, there are no electronic components on the whiteboard, only various pads. Mounting the electronic components on the PCB is SMT processing, that is, soldering the electronic components on the pads, and then use the DIP plug-in to assist the Assembly to complete the entire soldering process.