As you probably know, the life cycle and performance of circuit board assembly (PCBA) depends on the substrate of PCB board. Therefore, in order to choose the correct substrate, it is quite necessary to understand the materials used for different circuit board categories. That’s to say, understanding the electrical and physical properties of various substrates, which is going to help make a better decision in choosing substrate for PCB Assembly.

If a large amount of current need to be handled, the gap and width of circuit board will be also vital. The structural strength of the circuit board is determined by the base material and laminate. However, these two layer materials actually relies on the type of circuit board.

PCB Board Composition & Significance In PCB Assembly

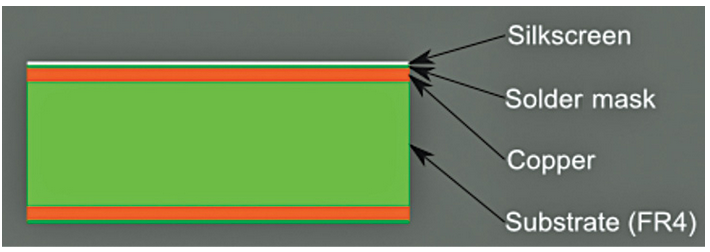

PCB board consists of four layers, namely substrate, laminate, solder mask and screen printing. The substrate and laminate together define the basic electrical, mechanical and thermal circuit board properties.

Substrate

FR4, a woven fiberglass cloth impregnated with an epoxy resin, is the most common material used for PCB substrates. Here, FR stands for fire retardant. It is suitable due to its rigidity and thickness. Besides, regarding flexible PCBs, Kapton or equivalent function plastics is to be used.

The board thickness depends on its application or purpose. For example, the thickness of most Sparkfun products is 1.6mm, while Arduino Pro products is 0.8mm. BTW, if PCB board is made of cheaper materials such as epoxy resin ,which will lack durability.

Substrates are found in low-cost consumer electronics products with low thermal stability, which causes them to lose lamination easily. As solder iron is fixed on the board for a long time, the substrate is also going to occur smoke, which makes electronics products easy to identify.

The Non-Conductive Layer Of Dielectric Material Selected Is Based On The Dielectric Constant

The substrate should satisfy certain required properties, such as glass transition temperature (Tg). Tg is the point at which heat causes the material to deform or soften. A variety of materials can be used for the substrate, such as aluminum or insulated metal substrate (IMS) FR-1 to FR-6, polytetrafluoroethylene (PTFE), CEM-1 to CEM-5, G-10 and G-11, RF-35, polyimide, alumina and flexible substrates such as Pyralux and Kapton.

In general, IMSes is able to minimize thermal resistance and conduct heat efficiently. These substrates are mechanically stronger than thick-film ceramic and direct-bonded copper structures which are commonly used in many applications."

Laminate

This provides properties such as coefficient of thermal expansion, tensile and shear strength, and Tg. Common dielectrics used for laminates are CEM-1 and CEM-3, FR-1, FR-4, polytetrafluoroethylene (Teflon), FR-2 to FR-6, CEM-1 to CEM-5 and G-10.

Copper foil is the next layer laminated to the board. For double-sided PCBs, copper is applied to both sides of the substrate. The thickness of copper varies in the light of different application. For example, compared to low-power applications, high-power applications are thicker correspondingly.

Solder Mask

This is the layer on top of the copper foil. Solder Mask can be used as an insulating material for copper traces to prevent accidental contact with other conductive metals. Apart from that, it also helps soldering in the right place.

When it comes to the significance of solder mask, we have to say, it is a protective layer that prevents external contamination and provides the required isolation between surface components such as pads, copper wires and drilled holes.

Silk Screen

Screen printing covers the solder mask and is used to add letters, numbers and symbols to the PCB for easy assembly and better understanding of the circuit board through indicators.

The Circuit Boards Can Be Classified Based On The Following Ways:

Component Position: Single-sided, double-sided and embedded

Stacking: Single and multi-layer

Design: Based on modules, customized or special

Flexibility: Rigid, flexible and rigid-flexible

Strength: Electrical strength and mechanical strength

Electrical Function: High frequency, high power, high density and microwave

The Board Type Can Be Used As The Most Suitable Board Material While PCB Design

Single-sided PCB only includes a thin copper plated substrate.In other words, it’s only place a protective solder mask on the copper layer. And the screen printing coating can be applied on the top to mark the elements of the board.

The substrate of a double-sided PCB includes a metal conductive layer and components attached to both sides (top and bottom).

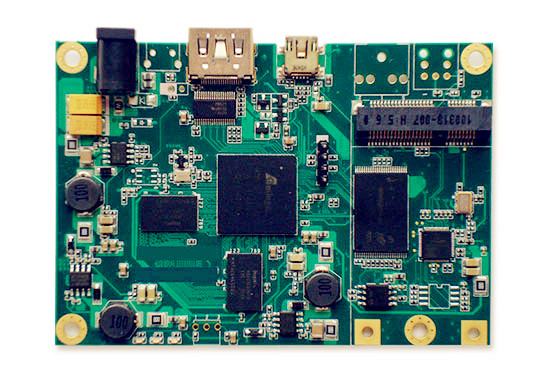

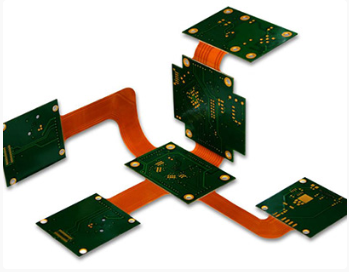

Multilayer PCBs increase the density and complexity of PCB design by adding additional layers beyond those seen in double-sided PCB configurations, which allow extremely thick and highly compound designs. The additional layer used is the power layer, which provides power to the circuit and reduces the level of electromagnetic interference (EMI).

Rigid PCBs use strong rigid substrate materials (such as fiberglass) to prevent the circuit board from twisting. The motherboard in a computer is exactly the best example of a non-flexible PCB.

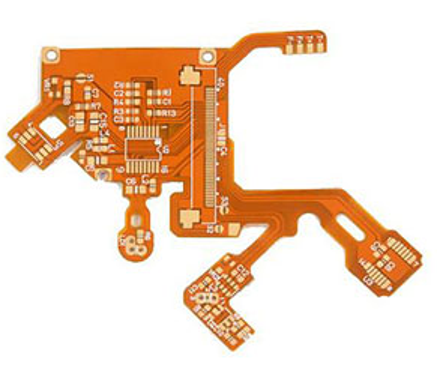

The substrate of the flexible PCB ( FPC ) is flexible plastic. FPC can be rotated and displaced during use without damaging the circuit on the PCB. In addition, it can restore heavy wiring in advanced gears where weight and space are critical, such as satellites.

Rigid-flex board consists of a rigid circuit board attached to a flexible circuit board. These boards is able to meet composite design requirements as needed.

Safety Precautions About Toxic Materials In PCB Assembly

The fumes in the solder may contain lead, which is toxic. However, solder is used to make electrical connections on the PCB, so the soldering operation must be performed in a closed environment. Smoke discharged into the atmosphere must be clean. One solution to replace wires and solder that is to use water-soluble conductive molding plastics.

Precautions About Heat Dissipation When Choosing PCB Substrates

The two factors that affect the PCB are power and heat. Therefore, it is important to determine each threshold. This can be done by evaluating the thermal conductivity of the PCB through the length of the material.

Unfortunately, PCB materials with low thermal conductivity generate heat, which can be a huge disadvantage for heat-intensive applications.

PCB Substrates Choosing For PCB Assembly

There are two types of PCBs, single-sided PCB and double-sided PCB, some of which are copper-clad, while others use aluminum in the military and aerospace, automotive and medical industries. For these specific areas, the materials used must have best performance.

Thus, choosing PCB substrates for the above mentiones products mainly considers those light weight, good quality or ability to withstand high power substrates. Since the material level is related to the performance level, it is important to determine which functions need to be compared with each other when choosing PCB substrates.

Most of flexible board ( FPC) is composed of Kapton, which is a polyimide film with heat resistance, dimensional consistency and dielectric constant of only 3.6. Kapton has three Pyralux versions: FR, non-flame retardant (NFR) and glue-free, high performance (AP).

Nevertheless, quality is important for the construction of any type of circuit board for household electronic equipment or industrial equipment. Components such as PCBs should provide excellent performance over the expected lifetime. Electronic equipment, microwave ovens and other household appliances rely on PCB technology to keep them working.

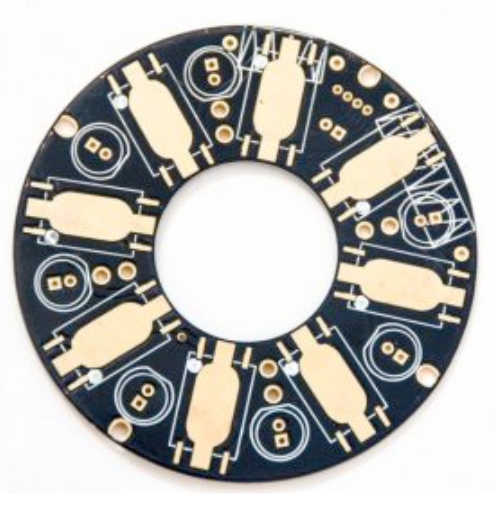

PCB Substrate Choosing for LED Lighting Products

Speaking of LED PCB board, it’s well known that they tend to generate heat during operation. Therefore, the LED chip should be mounted on a base made of metals such as aluminum, copper or alloy mixtures and coated with a highly reflective surface to achieve the best heat management and increase light output, which keeps the heat-generating components cool and improves their heat dissipation capacity. Furthermore, it will also improve the performance and life of the LED to some degree.

In a nutshell, choosing the metal core PCB (MC-PCB) for LED applications is most suitable. Including a thin layer of thermally conductive dielectric material, its heat transfer efficiency is much higher than traditional rigid PCB. What’s more, FR-4 material includes a layer of hot-dip aluminum, which is able to dissipate heat effectively. Thus, in view of the fact that MC-PCB materials are developed for higher power.