What is the function of PCBA testing?

PCBA testing is an extremely important part of the entire Electronic Manufacturing Services. It can strictly control the quality of shipments in the final stage, and find problems timely to adjust the previous processes such as SMT and DIP, optimize the process, and realize one. Detect the chain to control quality at all levels. A good PCBA test fixture can make the whole PCBA processing process more effective. Next, Shenzhen Grande will explain the key points of good PCBA test and treatment.

How many main points of PCBA test fixture production?

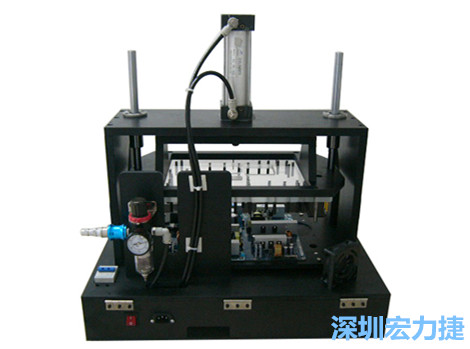

1. According to the test requirements and test board, after selecting the control method, the structure design of the fixture can be designed. The carrier board, the pressure plate, the connector module, etc. can be designed, and the carrier/platen of the fixture is reasonably avoided. There are corresponding protective measures during testing to avoid damage to the test board.

2. The positioning of the fixture is accurate, and the docking of the connector should be smooth.

3. The layout inside the fixture box is reasonable, and the space for wiring and installation control system is sufficient.

4, fiber / MIC / SPK / SIM card analog card position should be reserved, and the location of the area.

5. The position of the interface reserved for the fixture should be correct, sufficient, and the layout is reasonable.

6. The fixture body lock should be replaced by luggage buckle or press buckle to facilitate replacement of parts and maintenance.

7. Correct zero calibration. The zero drift of the test fixture changes with the change of the test conditions or the test fixture, so zero correction of the open circuit and short circuit is necessary. Therefore, the FCT test fixture has settings for open circuit and short circuit correction.

8. When the jig breaks and aging, you can change the needle and continue to use it. If the fixture is damaged and cannot be repaired and the customer changes are no longer used, it needs to be re-created.

PCBA test fixtures are typically tailor-made fixtures for a specific product that increase productivity and shipment quality.