What is the shielding cover?

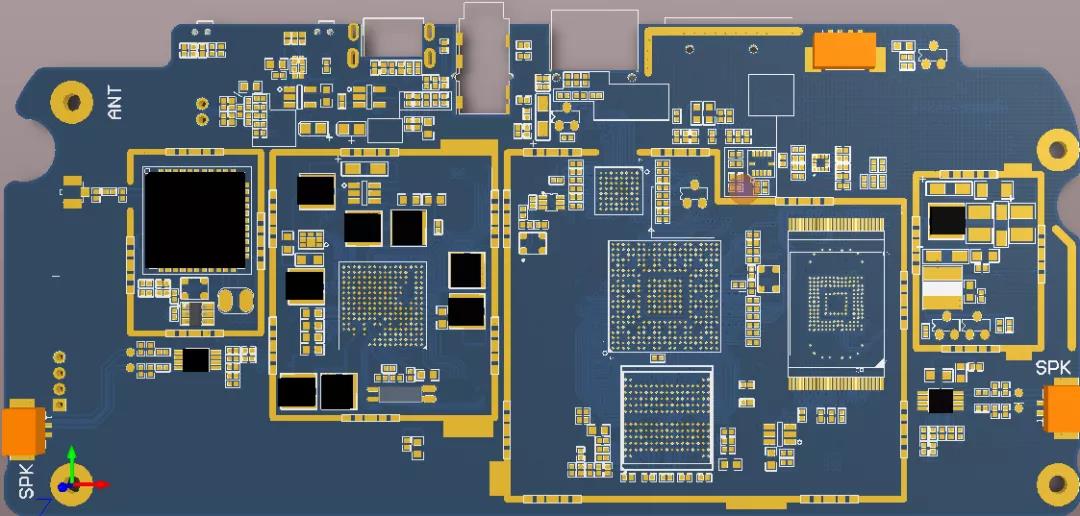

The shielding cover actually is an alloy metal cover, which is a vital component to reduce display radiation. It can effectively reduce the mutual interference between modules when used in MID or VR products. As shown in Figure 1, it is common in the main control function module. Isolation between the power supply module and the Wifi module.

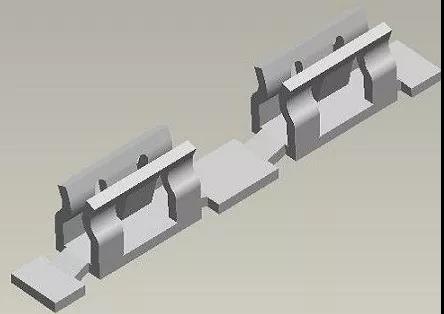

Figure 1 Use of shield

The purpose of shielding clip

Generally, there are products that use wireless communication. Usually, a shielding frame is designed on the circuit board to isolate electromagnetic interference (EMI), but for the shielding frame to function, two parts are generally needed, one is shielding framwhich can be processed via SMT Assembly, and the other is shielding cover, so that it is necessary to make more than two sets of press molds.

Now some fast-brained manufacturers have come up with a way to replace the shielding frame with a clip. This kind of clip can not only be processed by SMT Assembly, but also small in size so it is not afraid of deformation. In addition, such kind of clip is able to directly replace the shielding frame. After the clips are soldered to the circuit board, the shield can be directly installed in the middle of these clips and clamped, which is equivalent to reducing the cost of a shielding frame. As shown in picture 2

Figure 2 Commonly used shield clip

Although the shield clip has plenty of advantages, like saving cost, there are still many engineering design issues that we need pay attention to:

1. Is there any suggestion on how far away a clip should be placed? According to the manufacturer's answer, a clip of 25mm is generally sufficient.

2. Basically, we have designed and placed a shielding clip at the corners, which can make it easier for the operator to install the shielding cover accurately. Then in other places where there is no shielding clip, some grounded fabrics are also designed, which can slightly improve the electromagnetic isolation ability of the shielding cover, and on the other hand, it can be changed to a shielding frame immediately when the shielding clip is invalid. Redesign the circuit board.

Use shieding cover for modules

In PCB design of MID or VR products, certain modules are often to be shielded, such as,

1. Power module ( PMU+DCDC+LDO )

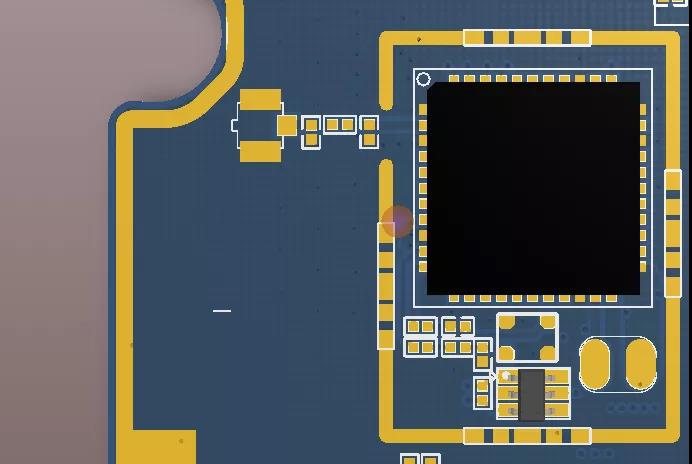

As shown in Figure 3, usually the power module exists on the PCB as a heat source and interference source, and a shielding cover is added to it to effectively reduce its external radiation interference.

Figure 3 The shielding cover of the power module

2. Core module ( CPU+DDR+Flash [EMMC] )

Due to the core module is the core part of PCB. Stable and undisturbed operation is an important part of a stable system. As a module susceptible to external interference, a shielding cover is usually designed for shielding, as shown in Figure 3.

3. Wifi and Bluetooth module

With the continuous increase of module integration, the WiFi module also integrates many other functions, like Bluetooth. The more integrated, it will naturally interfere with the reception of WiFi signals. Another main source of interference is the components on the PCB. When they work, the high-frequency circuits will produce strong interference. At this moment, most brand manufacturers will use shielding to remove or reduce the interference of the motherboard to the antenna. Metal shields are a good choice. They can effectively shield the electromagnetic waves from the internal The influence of the circuit, and which also blocks the electromagnetic waves generated inside from radiating outward. In the meanwhile, the location of the antenna is also vital. It is generally placed in a clean place on the side of the board, as shown in Figure 4, which demonstrates a Wifi Bluetooth module with a shielding cover.

Figure 4 Wifi Bluetooth module shield

Shielding cover and common design method of shielding cover

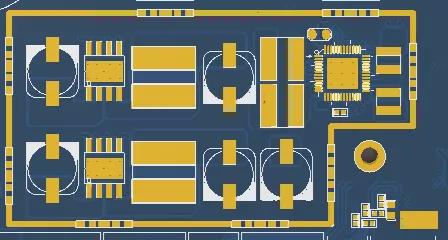

When designing the shielding cover, try to be rectangular and not polygonal, which increases the difficulty of production. As shown in Figure 5, it shows the commonly used drawing method and the placement of the shield clip.

Figure 5 Common design methods of shielding cover and shielding cover