PCB Electrical Testing

As the improvement of modern electronics and increasing complexities of electronic products, the days when only visual inspection is relied on have gone since visual inspection only works relatively well for double-layer PCBs and multi-layer PCBs prior to lamination. Nowadays, with the development of vias such as blind/buried vias, it's difficult for visual inspection to reach that far. So we we need to do electronic test to make sure the quality of the product.

Grande has been focusing on the high quality of its products. As a result, each piece of board has to be tested prior to playing a real role in customers' projects just in order to guarantee the smooth implementation of optimal performance and functions, which has been a crucial link in our PCB fabrication process.

Grande performs 100% electrical testing on all bare PCBs produced at its facilities as per IPC-9252 specifications.

There are some common way of PCB electrical testing:

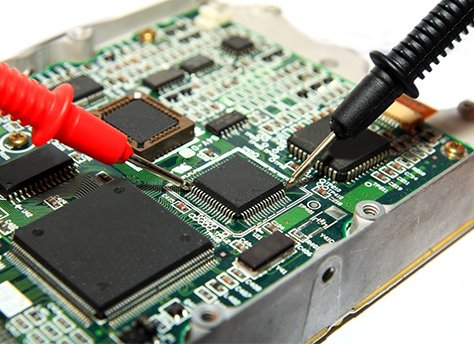

Bed of Nails Testing?

Bed of nails testing, also called a calm shell or universal grid, is implemented through dozens of stiff testing fixtures just like what its name is described.

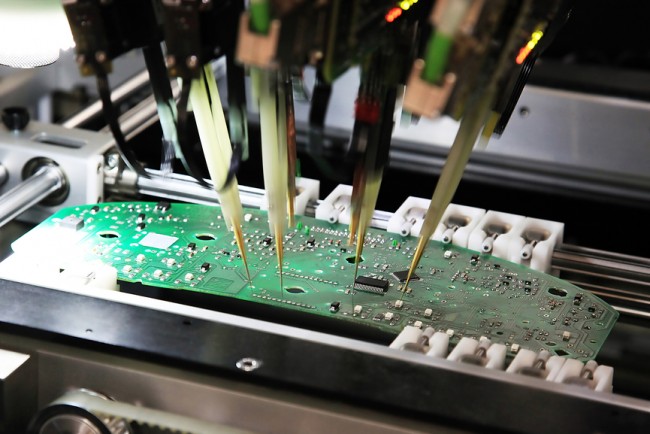

Flying Probe Testing?

Flying probe testing depends on moving probes to test electrical performance of each net on a bare circuit board.

No matter the bed of nails testing or flying probe testing, the tested items mainly including: opens, shorts, capacitance to resistance in a circuit on each bare board. In addition, some reports also can be summarized through testing results including cross section, solderability, peel strength etc. So that to help ideal performance and all functions of bare boards can be totally realized in your practical projects.

If you still have some problem about PCB electrical testing, please contact me at anytime.

|