It is mainly used, so that the flat head screw can sit flush with the surface to have a clean look and installation. To ensure correct design for manufacturing, most manufacturers require the details of the hole diameter. They also need to know if the hole is plated or not. Knowing if the hole is plate or not is critical because in some situations an unplated hole may be grounded to the framework, which could cause a problem that would require plating to correct. Countersinks usually have an 82 degree or a 90 degree angle; however, other angles are possible that the customer would need to provide to the PCB fabricator.

For accurate drilling of countersink holes, the following information is needed:

▪ Which side of the board is the countersink hole should be drilled, on top or bottom?

▪ Is the sink and shaft to be through plated or non-plated?

▪ Taper angle or countersink angle

▪ Countersink diameter

▪ The finished diameter of the shaft of the hole

▪ Depth of the countersink is to be drilled

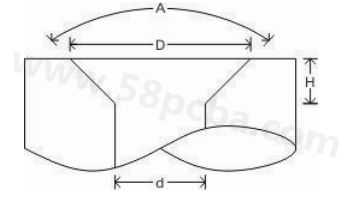

A: Countersink angle, D: Countersink Diameter, d: Hole diameter, H: Hole depth