What is PTF?

PTF (polymer thick film) should also be considered as a kind of flexible circuit board (Flex Cable), which uses a screen printing technique to print a conductive layer on PET. The circuit is formed on the substrate, and some more elaborately, a layer of insulating dielectric is applied to the conductive ink to protect the circuit. Different from the general FPCB copper foil basic corrosion process.

How about the application of PTF?

PTF general applications use single-layer lines, but can also be double-layer or multi-layer lines, insulated by insulating ink in the middle of the line, but a small line must be left as the connection of adjacent layer lines, no Can cover the insulating ink.

(↓ molded product of single layer PTF)

Single layer PTF molded article

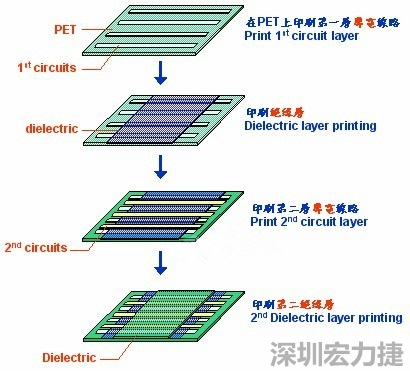

Double-layer ink manufacturing process

Step 1: The first layer of conductive traces are printed on the substrate of the PET. Some PETs are atomized to increase the adhesion of conductive inks. Conductive inks usually use a mixed ink of silver paste and conductive graphite as the main component, so it is cheaper than the copper foil substrate etching process of a general flexible circuit board. .

Step 2: The first layer of insulating ink is printed and covers the first layer of conductive lines to avoid short circuit with the second layer of conductive lines, but the line to be connected with the second layer of conductive lines must be reserved and cannot be covered. The insulating layer is usually made of UV ink, because it can be dried quickly, so it is baked by UV lamp after printing.

Step 3: Printing the second layer of conductive lines on the first layer of insulating ink, and paying attention to the place where the first layer of conductive lines are in contact.

Step 4: Printing the second layer of insulating ink and covering all conductive lines, with the exception of electrical and special requirements.

Double layer polymeric thick film (PTF) flexible circuit board process

What are the advantages of PTF?

▪ Low price and environmentally friendly: PTF flexible circuit boards use silver paste and conductive graphite and use screen printing to complete the layout of the circuit, which is much cheaper than the traditional traditional flexible circuit board using copper and gold plating process. And there is no electroplating process demand, more environmentally friendly.

▪ Short delivery: Since there is no electroplating process, the manufacturing process is much less than the traditional flexible circuit board and the drying time is short. The process time is short and the delivery time is of course short.

What are the disadvantages of PTF?

▪ It cannot be folded in half: FPC is printed with silver glue and graphite, and the ductility is not comparable to copper and gold. It is strongly recommended that PTF flexible boards cannot be folded in half.

▪ There is a minimum gap between the lines: the PTF manufacturer claims that the minimum space between the lines is 5 mils (0.127 mm), but the defect rate is very high; the general recommended minimum space between the lines is 20 mils (0.5 mm). ). The minimum line spacing between traditional flexible boards is 3 mils.

PTF: Polymer Thick Film

PET: Polyethylene terephthalate (polyethylene terephthalate)