If you work in the banking and finance industry, you must have heard of fiduciary responsibility. However, there are not many people who have switched from financial industry to electronic engineering. Therefore, in the field of PCBA technology manufacturing, the word may not have been heard by everyone. However, as long as the suffix "ry" of the trust is replaced by "l", it becomes a fiducial that electronic engineers must know!

What is the function of fiducial mask?

If the board is assembled with a pick and place machinery that automatically mounts the components on the board, the fiducial marks come in handy. The accuracy of the placement machine must be high enough to accurately place the 0201 resistor or the micro BGA of 2mm x 2mm wafer size. In addition, the machine also needs to know exactly where the board is.

Fiducial masks are designed for surface mounters, which ensure that the board is oriented correctly and placed in the exact position possible. The placement machine uses the camera to locate the fiducial mask, and then adjust the position of the internal components based on the exact position of the board. The entire process typically requires more than one irreversible fiducial mask.

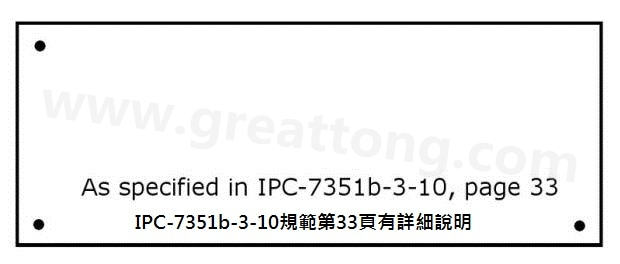

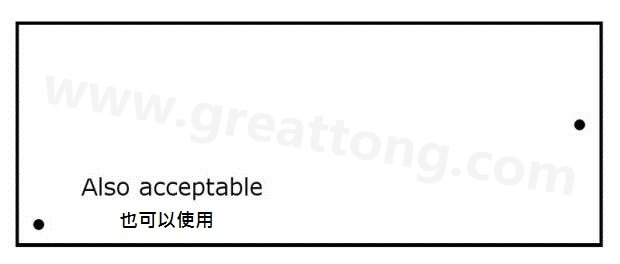

Take a look at the two images below, one with 3 fiducial masks and the other with 2 fiducial masks, which helps the machine to determine if the board is upside down or offset. There are 3 fiducial masks recommended by the International Printed Circuit Board Association (IPC). There are 2 fiducial masks, because the fiducial mask is irreversible, so it can also be used.

Image source: Screaming Circuits

Image source: Screaming Circuits

When do you use a fiducial mask?

PCBA mass production assembly must have fiducial mask assistance to ensure accurate registration and component placement. A small amount of PCBA assembly, such as a small amount of production or prototyping, is not necessary, but there are some exceptions, so you'd better confirm it in advance. Even if you don't need a fiducial mask to assemble a particular product, the fiducial mask is still useful, so it's always good, unless you're sure you rely on manual placement.

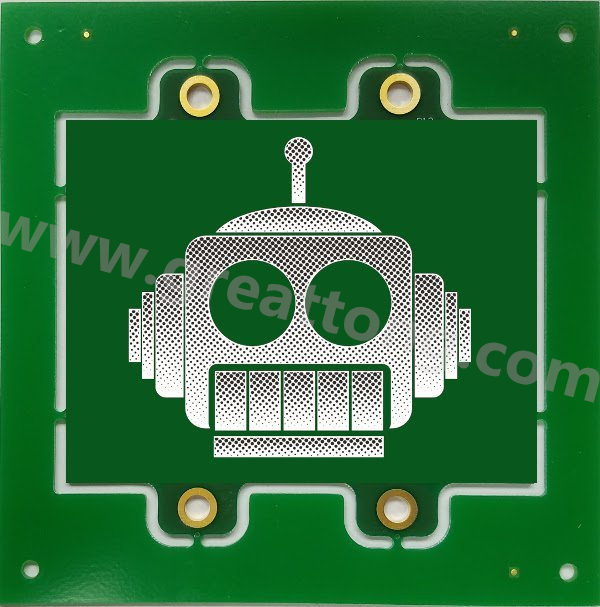

The picture below has three small metal points (upper left, upper right, lower right), which are all fiducial masks. If the internal components are completely dependent on manual placement, you do not need to use fiducial masks. However, because there are countless boards waiting to be assembled in the production line, the machine must first recognize the top, bottom, left and right of the board. You definitely don't want the component to be placed in the wrong place.

Image source: Screaming Circuits

How to design fiducial mask?

When it comes to the special construction of the fiducial mask, two things are particularly important: positional accuracy and contrast.

Position accuracy

The fiducial mask must be on the top copper layer. Why do you have to use copper, not screen printing or drilling? The answer lies in the registration! The top copper layer is placed once, so the position of the surface solder pad relative to the fiducial mask of the copper foil will never change. In contrast, the screen printing or drilling has one more procedure, so that the registration of each circuit board is completed. May be different.

Generally 0.4mm pitch BGA pads are 0.254mm (.01"), and the pitch between pads is 0.15mm (.0059"). Screen printing and drilling cannot achieve the precision required for registration.

Contrast

The camera of the set-top machine needs to receive a strong contrast, so the copper layer is not bare copper. Solder mask ink on the copper pad may reduce the contrast and make the camera difficult to identify. Solder-resistant inks have the same registration problems as screen printing, so you must make sure that the copper pads are clearly visible.

The diameter of the copper pad is about 1 to 2 mm, so the opening of the solder resist ink is 2 to 5 mm larger than the copper foil. Some CAD software suites have fiducial masks in the component library, which is the easiest way.

What is the fiducial mask shape?

The figure below is a close-up of the fiducial mask of the board. The anti-welding ink opening of this fiducial mask is square and generally round, but the shape of the opening is not that important. But the fiducial mask copper pad must be round!

Image source: Screaming Circuits

If your board comes from a board, you can place the fiducial mask on the rails of the board. If you are assembling individual boards, you can make the fiducial masks directly on the board. If you are not sure, you can do both, so you don't have to worry about assembling it on a board or assembling it on a board.

Don't forget, a small amount of manufacturing does not necessarily require a fiducial mask, but it is still worthwhile even if it doesn't work. The quality of electronic products is mostly related to risk management, so designing the board is very important!