Aspects Need Consider When Assembled PCB

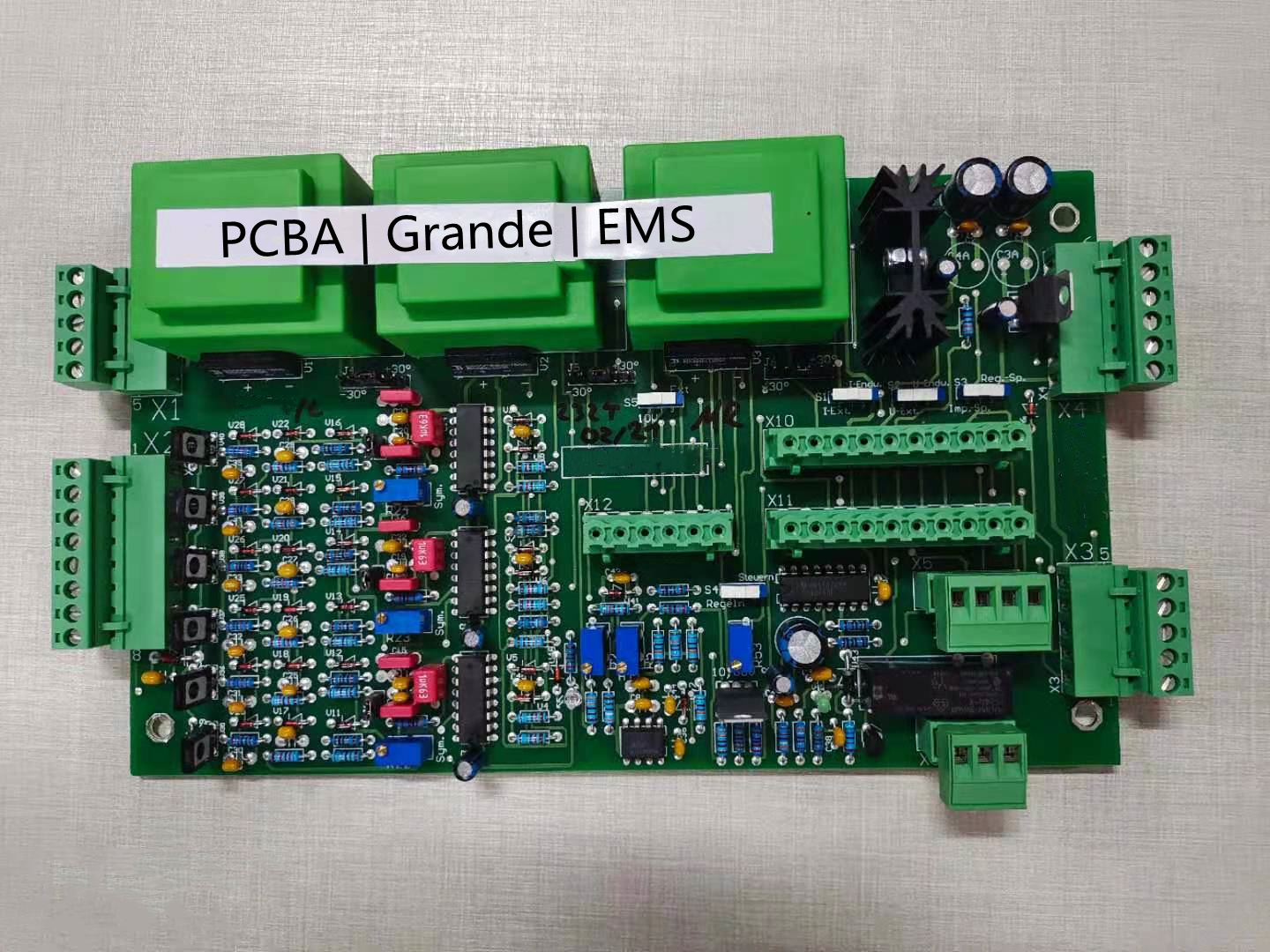

1. Design of Single Board Transmission and Positioning Elements for Automatic Production Line

For automated production line assembly, PCBA must have the ability to transmit edges and optical positioning symbols, because which is a prerequisite for production.

2. PCBA Process Design

The component layout structure of the components on the positive and negative of the PCBA determines the process method and path during assembly.

3. Component Layout Design

The position, direction and spacing design of components on the assembly surface. The layout of the components depends on the welding method used, and each welding method has specific requirements for the placement, direction and spacing of the components.

4. Assembly Manufacturability Design

The design for soldering through rate, through the matching design of pads, solder mask and stencil, realizes the stable distribution of solder paste quantitative and fixed points; Through the layout design, realizes the simultaneous melting and solidification of all solder joints of a single package; Through installation The reasonable connection design of the holes, the realization of 75% tin penetration rate, etc., these design goals are ultimately to improve the welding yield.

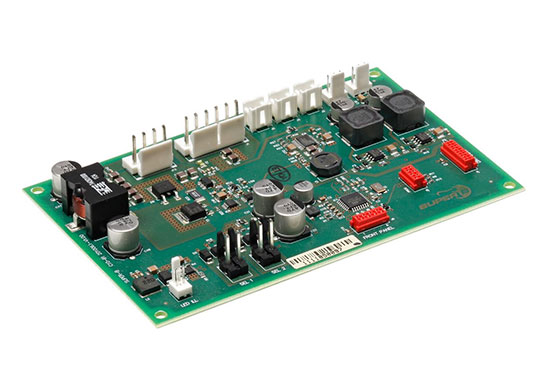

PCBA Precautions In Soldering

1. Warehouse personnel wear anti-static gloves when distributing materials and testing IQC, use the meter to be grounded reliably, and lay anti-static rubber pads on the work surface in advance.

2. In the process of operation, using anti-static work surface and anti-static container to hold components and semi-finished products. Department welding equipment can be grounded, and the electric soldering iron must be of anti-static type, and all equipment must be tested before use.

3. When the PCBA is processed through the furnace, because the pins of the plug-in components are washed by the tin flow, some plug-in components will be tilted after the furnace is soldered, causing the component body to exceed the silk screen frame, so the repair welding personnel after the tin furnace are required to perform it. Correct appropriately.

4. When PCBA is soldering speakers and batteries, do pay attention to the solder joints won’t have too much tin, because too much tin in solder joints is easy to cause short-circuit or fall off of peripheral components.

5. PCBA substrates must be placed neatly, and bare boards cannot be stacked directly. If need stack the boards, please use electrostatic bags.

Precautions for PCBA Finished Product Assembly

1. Use anti-static packaging bags for the whole machine without shell

Regularly inspect the anti-static tools, settings and materials to ensure that the working conditions meet the requirements.

2. Follow the procedure below when assembled the finished product

Warehouse → production line → production line upgrade software → assembly into a complete machine → QC test → write IMEI number → QA full inspection → restore factory settings → warehouse; Software must be upgraded before assembly, and it is not possible to upgrade the software after assembly into a finished machine. Unable to upgrade due to improper soldering, short circuit, work process problems and resulting in misjudgement of PCBA.