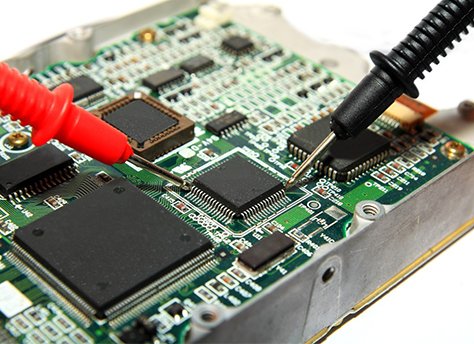

PCBA Boards can be reworked and repaired. However, only reasonable operations based on scientific guidelines can guarantee the quality of PCBA boards;

1. PCBA rework and repair basis

Rework and repair of PCBA must be performed in accordance with PCB design documents and repair regulations, and there also must be a unified rework and repair process.

2. The rework times allowed for each solder joint

Rework is allowed for defective solder joints, and rework for each solder joint shall not exceed three times, otherwise it will cause damage to the solder joints.

3. Use of removed components

In principle, the disassembled components should not be used anymore. If they need to be used, they must be screened and tested according to the original electrical performance and process performance of the components, and the installation is allowed only when they meet the requirements.

4. Times of desoldering on each pad

Each printed pad should be desoldered only once (that is, only one component is allowed to be replaced). The thickness of the intermetallic compound (IMC) of a qualified solder joint is 1.5~3.5μm, and the thickness will increase after remelting, even when it reaches 50µm, the solder joint becomes brittle, the solder strength decreases... As a result, there are serious reliability risks under vibration conditions;

And remelting IMC requires a higher temperature, otherwise the IMC cannot be removed. The copper-plated layer at the exit of the through hole is the thinnest, and the pad is easy to break from here after remelting; with the thermal expansion of the Z axis, the copper layer deforms, and the pad is separated due to the obstruction of the lead-tin solder joint.

In the case of lead-free, the entire pad will be pulled up. The PCB is delaminated after heating due to moisture in the glass fiber and epoxy resin, and the pad is easy to warp and separate from the substrate.

5. Bow and twist requirements for surface mounting and mixed mounting PCBA assembly and soldering

The bow and twist of surface mounting and mixed mounting PCBA assembly and welding are less than 0.75%.

6. Total times of PCB assembly repairs

The total times of repairs for PCB assembly is limited to six; In other words, excessive repairs and modifications affect PCBA reliability.

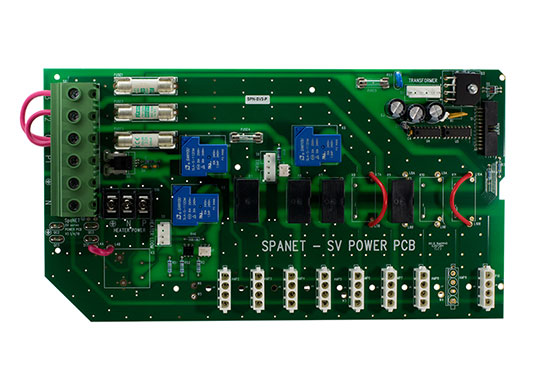

SMT Assembly Capability

1. The largest board: 310mm*410mm (SMT);

2. Maximum board thickness: 3mm;

3. Minimum board thickness: 0.5mm;

4. The smallest Chip parts: 0201 package or parts above 0.6mm*0.3mm;

5. The maximum weight of the mounted parts: 150 grams;

6. Maximum part height: 25mm;

7. The largest part size: 150mm*150mm;

8. Minimum lead part spacing: 0.3mm;

9. The smallest spherical part (BGA) spacing: 0.3mm;

10. The smallest spherical part (BGA) diameter: 0.3mm;

11. Maximum component placement accuracy (100QFP): 25um@IPC;

12. Mounting capacity: 3 to 4 million points/day.

Why Choosing Grande To Do PCB Assembly?

1. Strength Guarantee

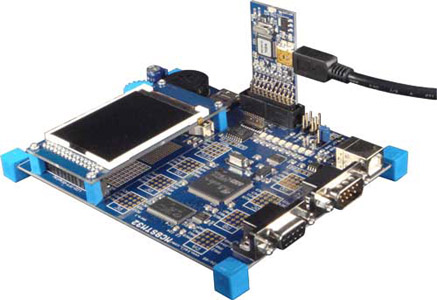

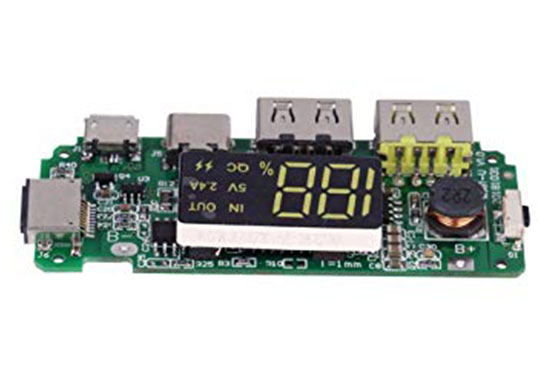

▪ SMT factory: With imported SMT machines and multiple optical inspection equipment, which is able to produce 4 million points per day. Each process is equipped with QC personnel who will keep an eye on product quality.

▪ DIP production line: Two wave soldering machines and more than 10 employees who have worked for over three years. That’ s to say, these workers are highly skilled and can weld various SMT & DIP components.

2. Quality Assurance With High Cost Performance

▪ High-end equipment can paste precision special-shaped parts, BGA, QFN, 0201 package. It can also be soldered prototype pcba via SMT machine and placing bulk materials by hand.

▪ Both samples, small and large batches can be produced. And there is no SMT Machine starting cost.

3. Rich Electronic Products SMT Soldering Experience With Stable Delivery

▪ Accumulated services to thousands of electronics companies, involving SMT soldering services for various types of automotive equipment and industrial control motherboards. Furthermore, PCBA products are often exported to Europe and the United States, and the quality is able to be affirmed by new and regular customers.

4. Strong Maintenance Ability & Reliable After-Sales Service

▪ The maintenance engineers have sophisticated experience so that those defective boards caused by all kinds of smt soldering can be repaired. Meanwhile, ensuring the connectivity rate of each circuit board also make sense.

▪Order problems feedback will get response, solution and solved as soon as possible.