Supplier: Shenzhen Grande Electronics

Layers: 4

PCB:FR-4/1.6mm, 1oz finished copper

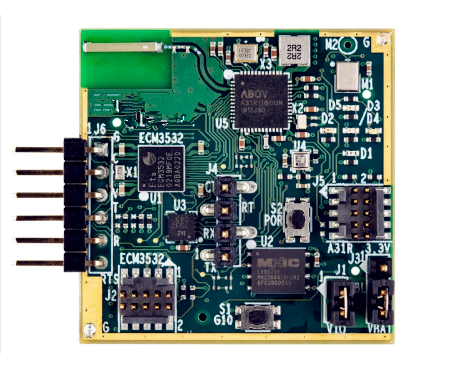

Application: LED Lighting Solutions Grande Electronics Fusion PCB Assembly - Turnkey Prototype PCBA

Surface Treatment: ENIG

PCBA Lead time:3-4 weeks

Packing: Anti-static bag and compartmental packing

Twist: <0.75%

【Description】

1, PCBA turnkey solution for LED Lighting Solutions Grande Electronics Fusion PCB Assembly - Turnkey Prototype PCBA.

2, PCB Assembly, PCB fabrication / PCB layout, PCB re-layout.

3, Electronic Manufacturing Service.

4, SMT&DIP&PTH&BGA.

5, Components Sourcing.

6, Quick PCBA prototype.

7, X-ray test, the Internal Circuit Test (ICT) , Function Test (FCT)

8, Sample and small batch order are accepted.

PCBA Service

Customer offers: Gerber file, PCB Specification, BOM and Assembly Drawing.

Full-turnkey PCBA: 1-30Layers PCB, Components Sourcing, SMT, PCBA testing, PCBA Aging test, PCBA Packing and PCBA Shipping.

PCBA Quality Assurance

1, Certifications: UL, SGS, TUV, BV, ROHS, ISO9001: 2008, TS16949: 2008

2, 7 lines dust-proof SMT lines and DIP lines.

3, All line workers wear anti-static and dust-proof clothing.

4, All operators should pass strictly training before they start work.

5, SMT Equipment:solder paste printer in Jidakang,, Mounter in Panasonic, Re-flow, Wave Soldering and Semi-auto DIP

6, PCBA Test Equipment: ORT, Constant temperature and humidity chamber,3D CMM,X-Ray.

7, PCBA Test:ICT, Functional Circuit Test and X-ray test.

8, Package Processed:

0402, 0603, 0805, 1206, 1608, 2125, 3216

Micro QFP 0.2mm

Flip-chip, BGA, Connectors

BGA Ball Pitch=0.2mm

9, Each workstation in accordance with the SOP

10, Materials:FR-4, FPC, Aluminum,High TG,Halogen-Free, HF, CEM-1, CEM-3, FR-1, 94-V0 and so on.

11, Material Brand:KB, SHENGYI, NANYA and so on.

PCBA Lead Time

PCBA prototype: 7-10 working days after contract signed and EQ confirmed.

Mass production: partial delivery according to the customer’s requirement.

Other information for PCBA

1, The mass production will be arranged after PCBA prototype confirmed.

2, Use Teflon adhesive tape to protect Mount Holes and GND Holes.

3, EPE is used to avoid impact and crash.

PCBA Standard Packing

Anti-static bag and compartmental packing