The goal is designing PCBs is to make them for the least amount of money while designing the best ways for them to perform well. Most people would say you cannot have both goals. However, new technological developments are helping engineers realize this goal by improving the high frequency electromagnetic interference performance and the quality of the design and at the same time keep costs down.

This technology is called Buried Capacitance. It is both patented and licensed across the world. It uses ZBC-2000 laminate material. In brief, it is a PCB producing methodology that spreads decoupled capacitance by inserting them in tiny dielectric layers inside the PCB and next to the power areas. This methodology essentially eliminates the need for decoupling capacitors. What this does is free up more space on the PCB and it helps designers make PCBS that have greater performance, or the same performance in a smaller board size.

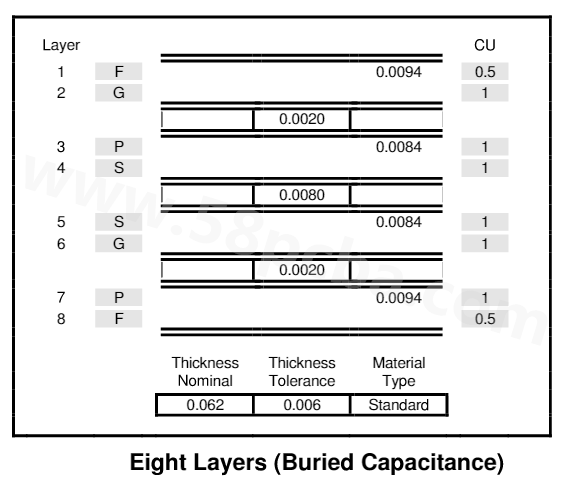

Desired Buried Capacitance Examples

The diagrams inserted below give the popular ways that Buried Capacitance can be used. If you need more information, you can get it from your board producer.