What is SMT Assembly?

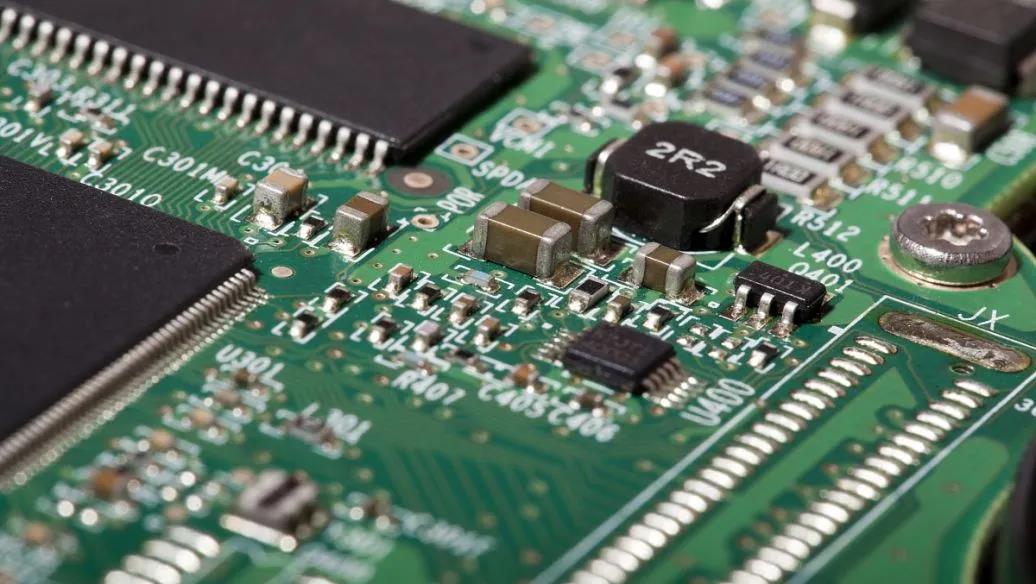

SMT Assembly means surface mount technology assembly. The specific content refers to the placement of schistose-shaped components or miniaturized components suitable for surface assembly on the surface of PCB as required, and then solder them using reflow soldering and other soldering processes to complete the technology of electronic components assembly. On the SMT circuit board, the solder joints and components are on the same side of the board, so on the PCB board processed by the SMT Assembly, the through holes are only used to connect the wires on both sides of the circuit board, and the number of holes is much less, so does the diameter of the hole. Furthermore, such a design can greatly improve the mounting density of PCB components.

Advantages of SMT Assembly

1. Miniaturization

The size and volume of chip components used in SMT Assembly are much smaller than those of traditional plug-in components, which can generally be reduced by 60% to 70%, or even by 90%. The weight is reduced by 60% to 90%, which cater for the development of miniaturization of electronic products.

2. High signal transmission speed

The PCB board processed processed by SMT Assembly has a compact structure and high mounting density, which can achieve the effect of short connection and low delay, and thus achieve high-speed signal transmission. At the same time, electronic products can be more resistant to vibration and shock.

3. High frequency characteristics

The components processed by SMT Assembly are generally leadless or short leads, which reduces the distribution parameters of the circuit and thus reduces radio frequency interference.

4. Conducive to automated production

SMT Assembly components have multiple characteristics such as size standardization, serialization and uniform welding conditions, which is able to make SMT Assembly a high degree of automation.

5. Low material cost

The packaging cost of most PCBA SMT Assembly components is already lower than that of plug-in processing components of the same type and function.

6. High production efficiency

SMT placement technology simplifies the production process of electronic products and reduces production costs. In addition, the entire PCBA production process is shortened as well as the production efficiency is improved.

SMT Assembly Capability

1. The largest board: 310mm*410mm (SMT);

2. Maximum board thickness: 3mm;

3. Minimum board thickness: 0.5mm;

4. The smallest Chip components: 0201 package or parts above 0.6mm*0.3mm;

5. The maximum weight of the mounted parts: 150 grams;

6. Maximum part height: 25mm;

7. The largest part size: 150mm*150mm;

8. Minimum lead components spacing: 0.3mm;

9. The smallest spherical components (BGA) spacing: 0.3mm;

10. The smallest spherical components (BGA) diameter: 0.3mm;

11. Maximum component placement accuracy (100QFP): 25um@IPC;

12. Mounting capacity: 3 to 4 million points/day.